“Ultrasonic Sensors: Precision Distance Measurement through Sound Waves for Diverse Applications”

Innledning

An ultrasonic sensor is a device that uses ultrasonic waves to measure distance or detect objects. It operates by emitting high-frequency sound waves, typically above the range of human hearing (20 kHz to several MHz), and then listening for the echo that bounces back from the target object. The time it takes for the echo to return is used to calculate the distance to the object based on the speed of sound. Ultrasonic sensors are widely used in various applications, including industrial automation, automotive parking assistance, robotics, and level measurement in tanks and silos. Their ability to provide accurate, non-contact measurements makes them valuable in environments where traditional sensors might fail due to dust, dirt, or other obstructions.

Introduction To Ultrasonic Sensors: Basics And Importance

Ultrasonic sensors are pivotal in modern technology, offering a versatile solution for a myriad of applications. These sensors operate on the principle of sound waves, specifically utilizing ultrasonic frequencies that are beyond the range of human hearing. By emitting ultrasonic waves and measuring the time it takes for the echoes to return, these sensors can determine the distance to an object with remarkable precision. This fundamental working principle underpins their widespread use in various industries, from automotive to healthcare.

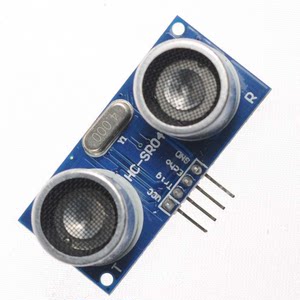

To delve deeper into the basics, an ultrasonic sensor typically comprises a transmitter and a receiver. The transmitter emits a burst of ultrasonic sound waves, which travel through the air until they encounter an object. Upon hitting the object, these waves are reflected back towards the sensor. The receiver then captures these reflected waves, and the sensor’s internal circuitry calculates the time interval between emission and reception. This time interval is directly proportional to the distance of the object from the sensor, allowing for accurate distance measurement.

The importance of ultrasonic sensors cannot be overstated. In the automotive industry, for instance, they are integral to parking assistance systems. By continuously monitoring the distance between the vehicle and nearby obstacles, these sensors help drivers park safely and avoid collisions. Similarly, in industrial automation, ultrasonic sensors are employed to detect the presence and position of objects on assembly lines, ensuring efficient and precise manufacturing processes.

Moreover, ultrasonic sensors play a crucial role in the healthcare sector. They are used in medical imaging, particularly in ultrasound machines, to create detailed images of internal body structures. This non-invasive diagnostic tool is invaluable for monitoring fetal development during pregnancy, diagnosing conditions, and guiding surgical procedures. The ability to provide real-time imaging without exposing patients to ionizing radiation underscores the significance of ultrasonic sensors in medical applications.

Transitioning to another vital application, ultrasonic sensors are also utilized in environmental monitoring. They can measure the level of liquids in tanks, rivers, and reservoirs, providing essential data for water management and flood prevention. Additionally, these sensors are employed in weather stations to measure wind speed and direction, contributing to accurate weather forecasting.

In the realm of robotics, ultrasonic sensors are indispensable for navigation and obstacle avoidance. Autonomous robots rely on these sensors to perceive their surroundings, enabling them to move safely and efficiently in dynamic environments. This capability is particularly beneficial in applications such as warehouse automation, where robots must navigate complex layouts and interact with various objects.

Furthermore, ultrasonic sensors are used in consumer electronics, enhancing the functionality of devices such as smartphones and smart home systems. For example, they enable touchless gesture control, allowing users to interact with their devices through simple hand movements. This technology not only adds convenience but also improves accessibility for individuals with disabilities.

In conclusion, ultrasonic sensors are a cornerstone of modern technology, offering precise and reliable distance measurement across a wide range of applications. Their ability to operate in diverse environments and provide accurate data makes them indispensable in industries such as automotive, healthcare, industrial automation, environmental monitoring, robotics, and consumer electronics. As technology continues to advance, the importance and utility of ultrasonic sensors are likely to grow, driving innovation and enhancing the capabilities of various systems and devices.

How Ultrasonic Sensors Work: Understanding The Working Principle

Ultrasonic sensors are fascinating devices that have found applications in various fields due to their ability to measure distance and detect objects with high precision. To understand how these sensors work, it is essential to delve into their working principle, which is rooted in the properties of sound waves. Ultrasonic sensors operate by emitting high-frequency sound waves, typically above the range of human hearing, and then measuring the time it takes for the echoes of these waves to return after bouncing off an object. This time-of-flight measurement is then used to calculate the distance to the object.

The process begins with the sensor’s transmitter emitting a burst of ultrasonic sound waves. These waves travel through the air until they encounter an object, at which point they are reflected back towards the sensor. The sensor’s receiver then detects the returning echoes. By precisely measuring the time interval between the emission of the sound waves and the reception of the echoes, the sensor can determine the distance to the object. This is based on the known speed of sound in air, which is approximately 343 meters per second at room temperature.

One of the key advantages of ultrasonic sensors is their ability to operate in various environmental conditions. Unlike optical sensors, which can be affected by lighting conditions and transparency of objects, ultrasonic sensors are largely immune to such factors. This makes them particularly useful in applications where visibility is poor or where objects are transparent or reflective. Additionally, ultrasonic sensors can detect objects regardless of their color or surface texture, providing a level of versatility that is highly valued in many industrial and commercial applications.

Transitioning to the practical applications of ultrasonic sensors, these devices are widely used in automotive systems for parking assistance and collision avoidance. In these applications, the sensors help drivers by detecting obstacles and providing auditory or visual warnings, thereby enhancing safety. Similarly, in industrial automation, ultrasonic sensors are employed for object detection, level measurement, and distance sensing. They play a crucial role in ensuring the smooth operation of automated systems by providing accurate and reliable measurements.

Furthermore, ultrasonic sensors are also utilized in the field of robotics, where they enable robots to navigate and interact with their environment. By continuously emitting and receiving ultrasonic waves, robots can map their surroundings, avoid obstacles, and perform tasks with a high degree of precision. This capability is particularly important in applications such as warehouse automation, where robots must move efficiently and safely in complex environments.

In addition to these applications, ultrasonic sensors are used in various other fields, including healthcare, where they are employed in medical imaging and diagnostic equipment. For instance, ultrasound machines use high-frequency sound waves to create images of internal body structures, aiding in the diagnosis and monitoring of medical conditions. The non-invasive nature of this technology makes it a valuable tool in modern medicine.

In conclusion, the working principle of ultrasonic sensors is based on the emission and reception of high-frequency sound waves, which allows for precise distance measurement and object detection. Their ability to operate in diverse environmental conditions and their versatility in detecting objects of different materials and textures make them indispensable in numerous applications. From automotive systems and industrial automation to robotics and healthcare, ultrasonic sensors continue to play a pivotal role in advancing technology and improving safety and efficiency across various domains.

Key Applications Of Ultrasonic Sensors In Various Industries

Ultrasonic sensors have become indispensable tools in various industries due to their ability to measure distance and detect objects with high precision. These sensors operate by emitting ultrasonic waves, which are sound waves at frequencies higher than the human ear can detect. When these waves hit an object, they bounce back to the sensor, which then calculates the distance based on the time it takes for the waves to return. This working principle allows ultrasonic sensors to perform reliably in a wide range of environments, making them highly versatile.

In the automotive industry, ultrasonic sensors are widely used for parking assistance systems. These sensors help drivers by detecting obstacles around the vehicle, providing real-time feedback to avoid collisions. The precision and reliability of ultrasonic sensors make them ideal for this application, as they can detect objects regardless of their shape, size, or material. Furthermore, these sensors are not affected by lighting conditions, which is a significant advantage over optical sensors.

Transitioning to the manufacturing sector, ultrasonic sensors play a crucial role in automation and quality control. They are used to measure the thickness of materials, detect flaws in products, and ensure that components are correctly positioned during assembly. For instance, in the production of plastic films, ultrasonic sensors can measure the thickness of the film with high accuracy, ensuring consistent product quality. Additionally, these sensors are employed in robotic systems to navigate and avoid obstacles, enhancing the efficiency and safety of automated processes.

In the field of agriculture, ultrasonic sensors are utilized for various applications, including level measurement in silos and tanks, and monitoring the growth of crops. By measuring the distance between the sensor and the surface of the stored material, farmers can accurately determine the level of feed, grain, or other substances in storage containers. This information is crucial for inventory management and ensuring that supplies are replenished in a timely manner. Moreover, ultrasonic sensors can be used to monitor the height of crops, providing valuable data for optimizing irrigation and fertilization practices.

The healthcare industry also benefits from the use of ultrasonic sensors, particularly in medical imaging and diagnostics. Ultrasonic sensors are the core technology behind ultrasound machines, which are used to create images of internal body structures. These images are essential for diagnosing various medical conditions, monitoring fetal development during pregnancy, and guiding surgical procedures. The non-invasive nature of ultrasonic imaging makes it a preferred choice for both patients and healthcare providers.

In environmental monitoring, ultrasonic sensors are employed to measure water levels in rivers, lakes, and reservoirs. This data is vital for flood prediction and management, as well as for ensuring the efficient operation of water treatment plants. Ultrasonic sensors can also be used to detect the presence of pollutants in water bodies, contributing to environmental protection efforts.

In summary, the key applications of ultrasonic sensors span across multiple industries, each benefiting from the unique capabilities of these devices. From enhancing vehicle safety and improving manufacturing processes to supporting agricultural practices and advancing medical diagnostics, ultrasonic sensors have proven to be versatile and reliable tools. Their ability to operate in diverse conditions and provide accurate measurements makes them an invaluable asset in modern technology and industry. As advancements in sensor technology continue, the potential applications of ultrasonic sensors are likely to expand even further, driving innovation and efficiency across various sectors.

Advantages And Limitations Of Using Ultrasonic Sensors

Ultrasonic sensors have become an integral part of modern technology, offering a range of advantages and some limitations that are important to consider. These sensors operate by emitting ultrasonic waves and measuring the time it takes for the waves to reflect back from an object. This time-of-flight measurement allows the sensor to calculate the distance to the object with a high degree of accuracy. The advantages of using ultrasonic sensors are numerous, making them a popular choice in various applications.

One of the primary advantages of ultrasonic sensors is their ability to measure distances accurately regardless of the material, color, or transparency of the object. Unlike optical sensors, which can be affected by the color or reflectivity of the target, ultrasonic sensors rely on sound waves, making them versatile in different environments. This characteristic makes them particularly useful in applications where the target object may be transparent or have varying surface properties.

Moreover, ultrasonic sensors are highly effective in harsh environmental conditions. They can operate reliably in dusty, humid, or dirty environments where optical sensors might fail. This robustness makes them ideal for industrial applications, such as in manufacturing plants or outdoor settings, where environmental factors can be unpredictable. Additionally, ultrasonic sensors are not affected by ambient light conditions, which means they can function effectively in both bright and dark environments.

Another significant advantage is the non-contact nature of ultrasonic sensors. Since they do not require physical contact with the object being measured, there is no risk of wear and tear on the sensor or the object. This non-invasive measurement method is particularly beneficial in applications involving delicate or hazardous materials, where contact-based measurement methods could be problematic.

Despite these advantages, ultrasonic sensors do have some limitations. One of the primary limitations is their relatively short range compared to other types of sensors, such as laser-based distance sensors. While ultrasonic sensors are excellent for short to medium-range measurements, they may not be suitable for applications requiring long-distance measurements. Additionally, the accuracy of ultrasonic sensors can be affected by the angle of the target surface. If the surface is angled or irregular, the reflected sound waves may not return directly to the sensor, leading to inaccurate measurements.

Another limitation is the potential for interference from other ultrasonic sources. In environments where multiple ultrasonic sensors are operating simultaneously, there is a risk of cross-talk, where the signals from different sensors interfere with each other. This interference can lead to erroneous readings and reduced accuracy. To mitigate this issue, careful planning and synchronization of sensor operation are required.

Furthermore, ultrasonic sensors can struggle with very small or thin objects. Since the sensor relies on the reflection of sound waves, objects that do not provide a sufficient reflective surface may not be detected accurately. This limitation can be a challenge in applications requiring the detection of fine or intricate details.

In conclusion, while ultrasonic sensors offer numerous advantages, including versatility, robustness, and non-contact measurement, they also come with certain limitations such as limited range, potential for interference, and challenges with small or angled objects. Understanding these advantages and limitations is crucial for selecting the appropriate sensor for a given application. By carefully considering the specific requirements and constraints of the application, one can leverage the strengths of ultrasonic sensors while mitigating their limitations, ensuring optimal performance and reliability.

Future Trends And Innovations In Ultrasonic Sensor Technology

As we delve into the future trends and innovations in ultrasonic sensor technology, it is essential to appreciate the remarkable advancements that have already been made. Ultrasonic sensors, which operate by emitting high-frequency sound waves and measuring the time it takes for the echoes to return, have become indispensable in various industries. Their ability to detect objects, measure distances, and sense proximity with high precision has paved the way for numerous applications. However, the journey of innovation is far from over, and the future holds even more promising developments.

One of the most significant trends in ultrasonic sensor technology is miniaturization. As industries demand more compact and efficient devices, researchers are focusing on reducing the size of ultrasonic sensors without compromising their performance. This trend is particularly evident in the medical field, where smaller sensors can be integrated into minimally invasive surgical tools, enhancing precision and patient outcomes. Additionally, miniaturized sensors are finding their way into consumer electronics, such as smartphones and wearable devices, enabling new functionalities like gesture recognition and enhanced user interfaces.

Another exciting development is the integration of artificial intelligence (AI) and machine learning (ML) with ultrasonic sensors. By leveraging AI and ML algorithms, ultrasonic sensors can now process and interpret data more intelligently. This integration allows for real-time decision-making and adaptive responses, making these sensors more versatile and capable. For instance, in autonomous vehicles, AI-enhanced ultrasonic sensors can improve obstacle detection and navigation, contributing to safer and more efficient transportation systems.

Moreover, advancements in materials science are playing a crucial role in the evolution of ultrasonic sensors. Researchers are exploring new materials that can enhance the sensitivity and durability of these sensors. Piezoelectric materials, which convert mechanical stress into electrical signals, are being engineered to achieve higher performance levels. These materials not only improve the accuracy of ultrasonic sensors but also extend their lifespan, making them more reliable for long-term use in harsh environments.

In addition to material innovations, the development of multi-sensor systems is gaining traction. By combining ultrasonic sensors with other types of sensors, such as infrared or optical sensors, multi-sensor systems can provide more comprehensive and accurate data. This synergy of different sensing technologies is particularly beneficial in complex applications like industrial automation and robotics, where precise and reliable information is crucial for optimal performance.

Furthermore, the Internet of Things (IoT) is driving the evolution of ultrasonic sensor technology. As IoT continues to expand, the demand for interconnected and smart devices is increasing. Ultrasonic sensors are being integrated into IoT networks, enabling real-time monitoring and control of various systems. For example, in smart cities, ultrasonic sensors can be used for traffic management, waste management, and environmental monitoring, contributing to more efficient and sustainable urban living.

Looking ahead, the future of ultrasonic sensor technology is undoubtedly bright. With ongoing research and development, we can expect even more innovative applications and improvements in performance. The convergence of miniaturization, AI integration, advanced materials, multi-sensor systems, and IoT connectivity will continue to push the boundaries of what ultrasonic sensors can achieve. As these trends unfold, ultrasonic sensors will play an increasingly vital role in shaping the technological landscape, driving progress across diverse industries and enhancing our everyday lives.

SPØRSMÅL OG SVAR

1. **What is an ultrasonic sensor?**

An ultrasonic sensor is a device that uses ultrasonic sound waves to measure the distance to an object.

2. **How does an ultrasonic sensor work?**

It emits ultrasonic waves and measures the time it takes for the waves to bounce back from an object, calculating the distance based on the speed of sound.

3. **What are the main components of an ultrasonic sensor?**

The main components are a transmitter (to emit sound waves), a receiver (to detect the reflected waves), and a control circuit.

4. **What are some common applications of ultrasonic sensors?**

Common applications include distance measurement, object detection, level sensing in tanks, and obstacle avoidance in robotics.

5. **What are the advantages of using ultrasonic sensors?**

Advantages include high accuracy, non-contact measurement, ability to work in various environmental conditions, and suitability for detecting transparent or shiny objects.

Konklusjon

An ultrasonic sensor is a device that uses ultrasonic waves to measure distance or detect objects. It works by emitting high-frequency sound waves and measuring the time it takes for the echo to return after bouncing off an object. The sensor calculates the distance based on the speed of sound in the medium. Ultrasonic sensors are widely used in various applications, including distance measurement, object detection, level sensing, and obstacle avoidance in robotics, automotive parking assistance, industrial automation, and medical imaging. Their ability to provide accurate and non-contact measurements makes them valuable in diverse fields.

Understood. What is your question?