“Keep Cool, Stay Efficient: Mastering the Art of Preventing Electronic Overheating”

Introduzione

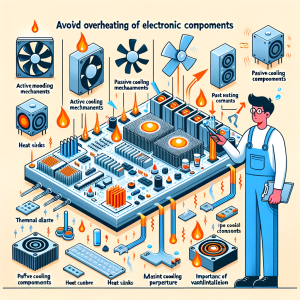

Overheating of electronic components is a critical issue that can lead to reduced performance, system failures, and even permanent damage to the devices. To ensure the longevity and reliability of electronic systems, it is essential to implement effective cooling strategies and thermal management techniques. This involves understanding the thermal characteristics of components, selecting appropriate cooling methods such as heat sinks, fans, and thermal interface materials, and designing circuits and enclosures that facilitate efficient heat dissipation. By proactively addressing thermal challenges, engineers can maintain optimal operating temperatures, enhance the durability of electronic devices, and prevent costly downtime and repairs.

Proper Ventilation Techniques

Ensuring proper ventilation is crucial to avoid the overheating of electronic components, which can lead to reduced performance, system failures, and even permanent damage. One of the most effective ways to maintain optimal temperatures is by implementing strategic ventilation techniques. By understanding and applying these methods, you can significantly enhance the longevity and reliability of your electronic devices.

To begin with, it is essential to recognize the importance of airflow within electronic enclosures. Proper airflow helps dissipate heat generated by components such as processors, power supplies, and other heat-sensitive parts. To achieve this, consider the placement of your devices. Positioning them in well-ventilated areas, away from walls or other obstructions, allows for better air circulation. Additionally, avoid stacking devices on top of each other, as this can trap heat and impede airflow.

Moreover, incorporating fans into your ventilation strategy can greatly improve cooling efficiency. Fans can be installed in various configurations, such as intake and exhaust, to create a continuous flow of air through the enclosure. Intake fans draw cool air into the system, while exhaust fans expel hot air out. This combination ensures that fresh air is constantly circulating, preventing heat buildup. When selecting fans, opt for those with adjustable speeds, as this allows you to fine-tune the airflow based on the specific cooling needs of your components.

In addition to fans, the use of heat sinks and thermal compounds can further enhance heat dissipation. Heat sinks are designed to absorb and disperse heat away from critical components. By attaching heat sinks to processors or other high-temperature parts, you can effectively reduce their operating temperatures. To maximize the efficiency of heat sinks, apply thermal compounds between the component and the heat sink. These compounds fill microscopic gaps, ensuring optimal thermal conductivity and improving overall heat transfer.

Another vital aspect of proper ventilation is regular maintenance. Dust and debris can accumulate over time, obstructing airflow and reducing the effectiveness of cooling mechanisms. To prevent this, periodically clean your devices and their ventilation systems. Use compressed air to remove dust from fans, heat sinks, and other components. Additionally, consider using dust filters on intake fans to minimize the amount of debris entering the system. Regular maintenance not only ensures optimal airflow but also extends the lifespan of your electronic components.

Furthermore, monitoring the temperature of your devices is essential for maintaining proper ventilation. Many modern systems come equipped with temperature sensors and monitoring software that provide real-time data on component temperatures. By keeping an eye on these readings, you can identify potential overheating issues early and take corrective action. If temperatures consistently exceed safe levels, consider upgrading your cooling solutions or reevaluating your ventilation setup.

Lastly, it is important to consider the ambient temperature of the environment in which your devices operate. High ambient temperatures can exacerbate overheating issues, making it more challenging to maintain optimal cooling. Ensure that your devices are placed in a climate-controlled environment, away from direct sunlight or other heat sources. If necessary, use air conditioning or additional cooling methods to maintain a stable ambient temperature.

In conclusion, proper ventilation techniques are essential for preventing the overheating of electronic components. By strategically positioning devices, incorporating fans, using heat sinks and thermal compounds, performing regular maintenance, monitoring temperatures, and considering ambient conditions, you can effectively manage heat and ensure the longevity and reliability of your electronic systems. Implementing these strategies will not only protect your investment but also enhance the overall performance of your devices.

Using Heat Sinks Effectively

In the realm of electronics, managing heat dissipation is crucial to maintaining the longevity and performance of components. One of the most effective methods to prevent overheating is the use of heat sinks. These devices are designed to absorb and dissipate heat away from electronic components, ensuring they operate within safe temperature ranges. To use heat sinks effectively, it is essential to understand their selection, installation, and maintenance.

Firstly, selecting the appropriate heat sink for your application is paramount. The choice depends on several factors, including the thermal resistance, size, and material of the heat sink. Thermal resistance, measured in degrees Celsius per watt (°C/W), indicates how efficiently a heat sink can transfer heat away from a component. A lower thermal resistance means better heat dissipation. Additionally, the size of the heat sink should be compatible with the available space in your device. Larger heat sinks generally offer better cooling but may not fit in compact designs. Materials also play a significant role; aluminum and copper are commonly used due to their excellent thermal conductivity. Copper, while more efficient, is heavier and more expensive than aluminum.

Once the appropriate heat sink is selected, proper installation is critical to ensure optimal performance. The interface between the heat sink and the electronic component must be as thermally conductive as possible. This is typically achieved by applying a thin layer of thermal paste or thermal adhesive. These substances fill microscopic gaps and irregularities on the surfaces, enhancing thermal contact. It is important to apply the thermal paste evenly and sparingly, as too much can impede heat transfer. After applying the thermal paste, the heat sink should be firmly attached to the component, ensuring even pressure distribution. Some heat sinks come with mounting clips or screws, while others may require additional brackets or adhesives.

In addition to proper installation, maintaining the heat sink is essential for sustained performance. Over time, dust and debris can accumulate on the heat sink’s fins, reducing its ability to dissipate heat. Regular cleaning is necessary to prevent this buildup. Compressed air can be used to blow away dust, while a soft brush can help remove more stubborn particles. It is also advisable to periodically check the thermal paste, as it can dry out and lose its effectiveness over time. Reapplying thermal paste when necessary can help maintain optimal thermal conductivity.

Moreover, considering the overall airflow within the device can enhance the effectiveness of heat sinks. Ensuring that there is adequate ventilation and that airflow paths are not obstructed can significantly improve heat dissipation. In some cases, adding fans or improving the placement of existing ones can help direct airflow over the heat sinks, further enhancing cooling efficiency.

In conclusion, using heat sinks effectively involves careful selection, proper installation, and regular maintenance. By understanding the thermal requirements of your electronic components and ensuring that heat sinks are appropriately chosen and maintained, you can significantly reduce the risk of overheating. This not only prolongs the lifespan of your devices but also ensures they operate at peak performance. As technology continues to advance, the importance of effective thermal management cannot be overstated, making heat sinks an indispensable tool in the arsenal of any electronics enthusiast or professional.

Importance Of Thermal Paste

In the realm of electronics, the importance of maintaining optimal operating temperatures for components cannot be overstated. One of the most effective ways to achieve this is through the use of thermal paste. This seemingly simple substance plays a crucial role in ensuring the longevity and performance of electronic devices. Understanding the significance of thermal paste and its proper application can make a substantial difference in preventing overheating and subsequent damage to electronic components.

Thermal paste, also known as thermal compound or thermal grease, is a thermally conductive material applied between the heat-generating component, such as a CPU or GPU, and the heat sink. The primary function of thermal paste is to fill microscopic imperfections and air gaps on the surfaces of these components. These gaps, though minuscule, can significantly impede the efficient transfer of heat. By filling these gaps, thermal paste ensures a more effective and uniform heat transfer from the component to the heat sink, thereby enhancing the cooling process.

The application of thermal paste is a critical step in the assembly of electronic devices. Without it, the heat generated by components can accumulate, leading to elevated temperatures that can cause thermal throttling, reduced performance, and even permanent damage. Therefore, it is essential to apply thermal paste correctly to maximize its effectiveness. A common mistake is applying too much or too little paste. An excessive amount can lead to spillage and potential short circuits, while an insufficient amount can leave gaps that compromise heat transfer. The goal is to apply a thin, even layer that covers the entire surface of the component.

Moreover, the quality of thermal paste is another factor that should not be overlooked. There are various types of thermal pastes available, each with different thermal conductivities and compositions. High-quality thermal pastes typically contain materials such as silver, ceramic, or carbon-based compounds, which offer superior thermal conductivity. Investing in a reputable thermal paste can provide better heat dissipation and longer-lasting performance compared to cheaper alternatives.

In addition to selecting the right thermal paste, it is also important to consider the reapplication of thermal paste over time. Thermal paste can dry out and lose its effectiveness after prolonged use, especially in high-performance systems that generate significant heat. Regular maintenance, including the periodic reapplication of thermal paste, can help maintain optimal thermal performance and prevent overheating.

Furthermore, the importance of thermal paste extends beyond just CPUs and GPUs. It is equally vital for other heat-generating components such as power transistors, voltage regulators, and memory modules. Ensuring that all critical components have adequate thermal management can significantly enhance the overall reliability and lifespan of electronic devices.

In conclusion, the importance of thermal paste in preventing the overheating of electronic components cannot be understated. By facilitating efficient heat transfer, thermal paste plays a pivotal role in maintaining the performance and longevity of electronic devices. Proper application, selection of high-quality paste, and regular maintenance are essential practices that can help avoid the detrimental effects of overheating. As technology continues to advance and electronic devices become more powerful, the role of thermal paste in thermal management will remain indispensable.

Choosing The Right Enclosure

When it comes to preventing the overheating of electronic components, choosing the right enclosure is a critical step that cannot be overlooked. The enclosure serves as the first line of defense against external environmental factors and plays a pivotal role in thermal management. To begin with, the material of the enclosure is of paramount importance. Metals such as aluminum and steel are excellent conductors of heat and can help dissipate heat away from the components. On the other hand, plastic enclosures, while lighter and often more cost-effective, may not offer the same level of thermal conductivity. Therefore, the choice of material should align with the specific thermal requirements of your electronic components.

In addition to material selection, the design of the enclosure also significantly impacts its ability to manage heat. Ventilation is a key factor to consider. Enclosures with strategically placed vents or perforations can facilitate airflow, allowing heat to escape and cooler air to circulate. This natural convection process can be further enhanced by incorporating fans or blowers, which actively move air through the enclosure. However, it is essential to ensure that these ventilation features do not compromise the enclosure’s ability to protect against dust, moisture, and other environmental hazards.

Moreover, the size of the enclosure should be carefully considered. An enclosure that is too small may not provide adequate space for air circulation, leading to hotspots and increased thermal stress on the components. Conversely, an overly large enclosure can be inefficient and may not offer the same level of protection. Striking the right balance between size and functionality is crucial for optimal thermal management.

Thermal insulation is another aspect that warrants attention. While it may seem counterintuitive, certain applications may benefit from insulating materials that prevent external heat sources from affecting the internal temperature of the enclosure. This is particularly relevant in environments with fluctuating temperatures or where the enclosure is exposed to direct sunlight. Reflective coatings or insulating foams can be employed to mitigate the impact of external heat.

Furthermore, the placement of components within the enclosure can influence thermal performance. Components that generate significant heat should be positioned in areas with maximum airflow. Additionally, heat sinks and thermal pads can be used to draw heat away from sensitive components and dissipate it more effectively. These thermal management accessories are particularly useful in densely packed enclosures where space is at a premium.

It is also worth considering the use of advanced thermal management technologies such as phase change materials (PCMs) and thermoelectric coolers. PCMs absorb and release heat as they change states, providing a passive cooling solution that can be highly effective in maintaining stable temperatures. Thermoelectric coolers, on the other hand, use the Peltier effect to create a temperature differential, actively cooling the components. While these technologies may come at a higher cost, they offer significant benefits in applications where precise temperature control is essential.

In conclusion, selecting the right enclosure for your electronic components involves a multifaceted approach that takes into account material, design, size, insulation, component placement, and advanced cooling technologies. By carefully considering these factors, you can create an environment that minimizes the risk of overheating and ensures the longevity and reliability of your electronic devices. As technology continues to evolve, staying informed about the latest advancements in thermal management will be key to maintaining optimal performance in increasingly demanding applications.

Regular Maintenance And Cleaning

Regular maintenance and cleaning are crucial steps in preventing the overheating of electronic components. Overheating can lead to reduced performance, shortened lifespan, and even catastrophic failure of electronic devices. Therefore, it is essential to adopt a proactive approach to ensure that your electronics remain in optimal condition.

To begin with, dust and debris are common culprits that can obstruct airflow and cause electronic components to overheat. Dust particles can accumulate on heat sinks, fans, and other cooling mechanisms, thereby impeding their ability to dissipate heat effectively. Consequently, it is imperative to clean these components regularly. Using compressed air is an effective method to remove dust from hard-to-reach areas without causing damage. Additionally, a soft brush can be employed to gently dislodge dust from delicate parts.

Moreover, it is important to inspect and clean the ventilation grilles and filters of electronic devices. These components are designed to facilitate airflow and prevent overheating. However, they can become clogged with dust and debris over time. By cleaning these grilles and filters, you can ensure that air can flow freely, thereby enhancing the cooling efficiency of your devices.

In addition to cleaning, regular maintenance involves checking the condition of thermal paste and thermal pads. These materials are used to improve the thermal conductivity between electronic components and their heat sinks. Over time, thermal paste can dry out and lose its effectiveness, leading to increased temperatures. Therefore, it is advisable to replace the thermal paste periodically to maintain optimal thermal performance. Similarly, thermal pads should be inspected for wear and replaced if necessary.

Furthermore, it is essential to monitor the performance of cooling fans. Fans play a critical role in maintaining the temperature of electronic components by circulating air and dissipating heat. However, they can become less effective due to wear and tear or the accumulation of dust. Regularly checking the condition of fans and ensuring that they are functioning properly can help prevent overheating. If a fan is found to be faulty or inefficient, it should be replaced promptly.

Another important aspect of regular maintenance is ensuring that electronic devices are not operating in environments that are prone to high temperatures. Excessive ambient temperatures can exacerbate the risk of overheating. Therefore, it is advisable to keep electronic devices in well-ventilated areas and avoid placing them near heat sources such as radiators or direct sunlight. Additionally, using cooling pads or external fans can provide supplementary cooling, especially for devices that are prone to overheating.

Moreover, it is beneficial to keep an eye on the temperature readings of your electronic components. Many modern devices come equipped with temperature sensors that can provide real-time data on the operating temperatures of various components. By monitoring these readings, you can identify potential issues before they escalate into serious problems. If you notice that a component is consistently running at high temperatures, it may be an indication that maintenance or cleaning is required.

In conclusion, regular maintenance and cleaning are essential practices to prevent the overheating of electronic components. By keeping dust and debris at bay, ensuring proper airflow, and monitoring the condition of cooling mechanisms, you can significantly reduce the risk of overheating. Adopting these proactive measures will not only enhance the performance and longevity of your electronic devices but also provide peace of mind knowing that they are operating within safe temperature ranges.

Conclusione

To avoid overheating of electronic components, ensure proper ventilation and airflow within the device, use heat sinks and thermal pads to dissipate heat, employ cooling fans or liquid cooling systems for active cooling, select components with appropriate power ratings, avoid overclocking, and regularly clean dust and debris from cooling systems. Additionally, consider using thermal management software to monitor temperatures and adjust performance as needed.