“Silicon and Germanium: The Building Blocks of Transistors”

Sissejuhatus

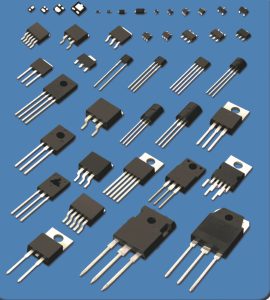

Transistors, the fundamental building blocks of modern electronic devices, are typically constructed using two primary materials: silicon and germanium. Silicon, the most widely used material, is favored for its excellent semiconductor properties, abundance, and cost-effectiveness. It forms the basis of most integrated circuits and is integral to the operation of computers, smartphones, and other electronic devices. Germanium, although less common than silicon, was historically significant in the development of early transistors and is still used in certain high-speed and high-frequency applications due to its superior electron mobility. Both materials have unique properties that make them suitable for different types of transistor applications, contributing to the versatility and efficiency of modern electronics.

Silicon Vs. Germanium: A Comparative Analysis

Transistors, the fundamental building blocks of modern electronic devices, are primarily constructed using two materials: silicon and germanium. These semiconductors have distinct properties that make them suitable for different applications, and understanding their comparative advantages and limitations is crucial for optimizing electronic performance.

Silicon, the most widely used semiconductor material, owes its popularity to several key factors. Firstly, silicon is abundant in the Earth’s crust, making it relatively inexpensive and readily available. This abundance translates to cost-effective production processes, which is a significant advantage for large-scale manufacturing. Additionally, silicon has a higher thermal conductivity compared to germanium, allowing it to dissipate heat more efficiently. This property is particularly important in high-power applications where excessive heat can degrade performance or even damage the device.

Moreover, silicon’s bandgap energy, which is the energy required to move an electron from the valence band to the conduction band, is 1.1 eV (electron volts). This bandgap is wide enough to ensure that silicon transistors have low leakage currents at room temperature, thereby enhancing their efficiency and reliability. Silicon also forms a stable and robust oxide layer (silicon dioxide) when exposed to oxygen, which is beneficial for creating insulating layers in integrated circuits. This oxide layer is crucial for the fabrication of metal-oxide-semiconductor field-effect transistors (MOSFETs), which are integral to modern electronics.

On the other hand, germanium was the first material used in the development of transistors and still holds certain advantages. Germanium has a smaller bandgap energy of 0.66 eV, which allows for higher electron mobility. This higher mobility means that germanium transistors can operate at higher speeds compared to their silicon counterparts. Consequently, germanium is often preferred in applications requiring high-frequency performance, such as radio frequency (RF) and microwave technologies.

However, germanium’s smaller bandgap also results in higher leakage currents at room temperature, which can be a drawback in many applications. Additionally, germanium is less abundant than silicon, making it more expensive and less practical for mass production. Germanium also lacks the ability to form a stable oxide layer, which complicates the fabrication of certain types of transistors and integrated circuits.

Despite these challenges, advancements in semiconductor technology have led to the development of silicon-germanium (SiGe) alloys, which combine the benefits of both materials. SiGe transistors leverage the high-speed capabilities of germanium while maintaining the thermal stability and cost-effectiveness of silicon. This hybrid approach has found applications in high-speed communication systems and advanced computing technologies.

In conclusion, the choice between silicon and germanium for constructing transistors depends on the specific requirements of the application. Silicon’s thermal stability, cost-effectiveness, and ability to form a stable oxide layer make it the preferred material for most electronic devices. In contrast, germanium’s higher electron mobility makes it suitable for high-speed and high-frequency applications, despite its higher cost and leakage currents. The development of SiGe alloys represents a promising compromise, offering enhanced performance by combining the strengths of both materials. As technology continues to evolve, the ongoing research and innovation in semiconductor materials will undoubtedly lead to even more efficient and versatile electronic devices.

The Role Of Silicon In Modern Transistor Technology

Silicon has long been the cornerstone of modern transistor technology, playing a pivotal role in the development and advancement of electronic devices. Transistors, the fundamental building blocks of integrated circuits, are primarily constructed using two materials: silicon and germanium. These semiconductors have unique properties that make them ideal for controlling electrical currents, which is essential for the functionality of transistors.

Silicon, the most widely used material in transistor construction, owes its popularity to several key factors. Firstly, silicon is abundant and relatively inexpensive, making it a cost-effective choice for mass production. Its natural abundance in the Earth’s crust ensures a steady supply, which is crucial for the large-scale manufacturing of electronic components. Additionally, silicon’s excellent thermal stability allows it to operate efficiently at high temperatures, a critical requirement for many electronic applications.

Moreover, silicon’s electrical properties make it particularly suitable for use in transistors. It has a moderate bandgap of 1.1 eV, which provides a good balance between conductivity and insulation. This bandgap allows silicon transistors to switch on and off effectively, enabling the precise control of electrical currents. Furthermore, silicon can be easily doped with impurities to modify its electrical characteristics, enhancing its versatility in various applications. For instance, doping silicon with phosphorus or boron can create n-type or p-type semiconductors, respectively, which are essential for forming the p-n junctions in transistors.

In contrast, germanium was the first material used in the early development of transistors. Germanium transistors were instrumental in the initial stages of semiconductor technology, but they have largely been supplanted by silicon due to several limitations. Germanium has a smaller bandgap of 0.66 eV, which makes it more susceptible to leakage currents and less efficient at high temperatures. However, germanium still finds niche applications in certain high-speed and high-frequency devices due to its higher electron mobility compared to silicon. This property allows germanium transistors to operate faster, making them suitable for specific applications where speed is paramount.

Despite the dominance of silicon, ongoing research continues to explore the potential of combining silicon with other materials to enhance transistor performance. For example, silicon-germanium (SiGe) alloys have been developed to leverage the advantages of both materials. SiGe transistors offer improved speed and performance while maintaining the thermal stability and cost-effectiveness of silicon. This hybrid approach has led to significant advancements in high-frequency and high-speed applications, such as wireless communication and radar systems.

In addition to SiGe, other materials like gallium arsenide (GaAs) and indium phosphide (InP) are also being investigated for their potential in specialized applications. These compound semiconductors offer superior electron mobility and higher frequency performance compared to silicon, making them attractive for certain high-performance devices. However, their higher cost and more complex manufacturing processes have limited their widespread adoption in mainstream transistor technology.

In conclusion, silicon remains the primary material used in modern transistor technology due to its abundance, cost-effectiveness, and favorable electrical properties. Germanium, while less commonly used today, still plays a role in specific high-speed applications. The ongoing exploration of silicon-based alloys and compound semiconductors continues to push the boundaries of transistor performance, ensuring that these tiny yet powerful devices remain at the heart of our ever-evolving electronic world.

Germanium Transistors: Applications And Advantages

Germanium transistors, one of the two primary materials used in the construction of transistors, have played a significant role in the evolution of electronic devices. Alongside silicon, germanium has been instrumental in the development of semiconductor technology. Germanium transistors, although less common today compared to their silicon counterparts, offer unique advantages and find applications in specific areas where their properties are particularly beneficial.

Germanium, a metalloid element, was one of the first materials used in the creation of transistors. The choice of germanium in the early days of semiconductor technology was due to its superior electron mobility compared to silicon. This higher electron mobility allows for faster switching speeds, which is a critical factor in high-frequency applications. Consequently, germanium transistors were widely used in the 1950s and 1960s for radio frequency (RF) and microwave applications, where speed and efficiency were paramount.

One of the primary advantages of germanium transistors is their low forward voltage drop. This characteristic makes them highly efficient in low-voltage applications, as they require less energy to operate. This efficiency is particularly advantageous in battery-powered devices, where conserving power is essential. Additionally, germanium transistors exhibit excellent performance at low temperatures, making them suitable for applications in cryogenics and space exploration, where extreme conditions are prevalent.

Despite these advantages, germanium transistors have some limitations that have led to the predominance of silicon in modern semiconductor technology. One significant drawback is germanium’s lower thermal stability compared to silicon. Germanium transistors are more susceptible to thermal runaway, a condition where an increase in temperature leads to a further increase in current, potentially causing the device to fail. This limitation makes germanium less suitable for high-power applications where heat dissipation is a critical concern.

Moreover, germanium is more expensive and less abundant than silicon, which has contributed to its decline in widespread use. Silicon, being the second most abundant element in the Earth’s crust, is more cost-effective and readily available. Additionally, silicon dioxide, a natural insulator, forms a stable and protective layer on silicon surfaces, which is advantageous for the fabrication of integrated circuits. This natural oxide layer is not present in germanium, complicating the manufacturing process and further reducing its appeal for large-scale production.

Nevertheless, germanium transistors continue to find niche applications where their unique properties are indispensable. For instance, in the field of analog signal processing, germanium transistors are valued for their superior linearity and low noise characteristics. These attributes make them ideal for use in audio amplifiers and other precision analog circuits, where maintaining signal integrity is crucial.

In conclusion, while silicon has largely overshadowed germanium in the realm of semiconductor technology, germanium transistors still hold a place in specific applications where their distinct advantages are required. Their high electron mobility, low forward voltage drop, and excellent low-temperature performance make them suitable for high-frequency, low-voltage, and extreme environment applications. However, the limitations of thermal stability, cost, and manufacturing complexity have restricted their widespread adoption. As technology continues to advance, the unique properties of germanium transistors may yet find new and innovative applications, ensuring their continued relevance in the ever-evolving landscape of electronics.

Historical Evolution: From Germanium To Silicon Transistors

The historical evolution of transistors has been marked by significant advancements in materials science, leading to the development of more efficient and reliable electronic devices. Initially, germanium was the material of choice for constructing transistors. Germanium, a metalloid with excellent semiconductor properties, was used in the first practical transistor developed by John Bardeen, Walter Brattain, and William Shockley at Bell Labs in 1947. This breakthrough marked the beginning of the semiconductor revolution, as germanium transistors offered a substantial improvement over vacuum tubes in terms of size, power consumption, and reliability.

However, germanium transistors had certain limitations that prompted researchers to explore alternative materials. One of the primary drawbacks of germanium was its relatively low bandgap energy, which made it less effective at higher temperatures. This limitation hindered the performance and reliability of germanium-based transistors in various applications, particularly those requiring high-temperature operation. Consequently, the search for a more suitable semiconductor material led to the discovery and subsequent adoption of silicon.

Silicon, another group IV element, emerged as a superior alternative to germanium due to its higher bandgap energy and better thermal stability. The transition from germanium to silicon transistors began in the late 1950s and early 1960s, driven by the need for more robust and versatile semiconductor devices. Silicon’s higher bandgap energy allowed it to operate efficiently at higher temperatures, making it ideal for a broader range of applications. Additionally, silicon’s abundance in the Earth’s crust made it a more cost-effective material for large-scale production.

The development of silicon transistors was further accelerated by advancements in silicon purification and crystal growth techniques. The Czochralski process, for instance, enabled the production of high-purity silicon crystals, which were essential for fabricating reliable and high-performance transistors. Moreover, the introduction of planar technology by Jean Hoerni in 1959 revolutionized the manufacturing process, allowing for the creation of integrated circuits with multiple transistors on a single silicon wafer. This innovation paved the way for the rapid miniaturization and increased complexity of electronic devices.

As silicon transistors became the industry standard, their performance continued to improve through various technological innovations. The development of metal-oxide-semiconductor field-effect transistors (MOSFETs) in the 1960s, for example, significantly enhanced the efficiency and scalability of silicon-based devices. MOSFETs, which utilize a thin layer of silicon dioxide as an insulating gate, offered lower power consumption and higher switching speeds compared to their bipolar junction transistor (BJT) counterparts. This advancement was instrumental in the proliferation of digital electronics and the subsequent growth of the semiconductor industry.

In summary, the historical evolution of transistors from germanium to silicon has been a pivotal journey in the field of electronics. Germanium’s initial success laid the foundation for the development of semiconductor devices, but its limitations necessitated the search for a more suitable material. Silicon emerged as the preferred choice due to its superior thermal stability, higher bandgap energy, and cost-effectiveness. The transition to silicon transistors was facilitated by advancements in purification and manufacturing techniques, leading to the creation of increasingly sophisticated and efficient electronic devices. Today, silicon remains the cornerstone of the semiconductor industry, driving innovation and enabling the continued advancement of technology.

Future Trends: Beyond Silicon And Germanium In Transistor Design

Transistors, the fundamental building blocks of modern electronic devices, have traditionally been constructed using two primary materials: silicon and germanium. These semiconductors have been the cornerstone of the electronics industry for decades, enabling the development of everything from simple radios to complex supercomputers. However, as the demand for faster, smaller, and more efficient devices continues to grow, researchers are exploring new materials that could potentially surpass the limitations of silicon and germanium.

Silicon, the most widely used material in transistor construction, owes its popularity to its abundance, cost-effectiveness, and favorable electrical properties. Silicon transistors have been the driving force behind Moore’s Law, which predicts the doubling of transistors on a microchip approximately every two years. This relentless miniaturization has led to exponential increases in computing power and efficiency. Nevertheless, silicon transistors are approaching their physical limits, particularly in terms of size and heat dissipation. As transistors shrink to the nanometer scale, issues such as quantum tunneling and leakage currents become more pronounced, posing significant challenges to further miniaturization.

Germanium, on the other hand, was one of the first materials used in transistor construction before silicon became dominant. Germanium transistors offer higher electron mobility than silicon, which can translate to faster switching speeds and improved performance. However, germanium is less abundant and more expensive than silicon, and it also suffers from higher leakage currents. Despite these drawbacks, germanium is still used in certain high-speed and high-frequency applications where its superior electron mobility provides a distinct advantage.

In light of the limitations of silicon and germanium, researchers are investigating alternative materials that could revolutionize transistor design. One promising candidate is graphene, a single layer of carbon atoms arranged in a hexagonal lattice. Graphene exhibits exceptional electrical conductivity, mechanical strength, and thermal properties. Its high electron mobility could enable transistors to operate at much higher speeds than those made from silicon or germanium. However, integrating graphene into existing semiconductor manufacturing processes presents significant technical challenges, and researchers are still working to overcome these hurdles.

Another material garnering attention is molybdenum disulfide (MoS2), a two-dimensional semiconductor with a direct bandgap. Unlike graphene, which lacks a bandgap, MoS2 can be used to create transistors that can be easily switched on and off. This property makes MoS2 a promising candidate for low-power electronic applications. Additionally, MoS2 transistors can be fabricated on flexible substrates, opening up possibilities for flexible and wearable electronics. Despite its potential, MoS2 is still in the early stages of research, and more work is needed to fully understand its properties and optimize its performance.

Furthermore, compound semiconductors such as gallium nitride (GaN) and indium gallium arsenide (InGaAs) are also being explored for their potential to outperform silicon and germanium in certain applications. GaN, for instance, is known for its high breakdown voltage and efficiency at high frequencies, making it ideal for power electronics and radio frequency (RF) applications. InGaAs, with its high electron mobility, is being investigated for use in high-speed and high-frequency transistors.

In conclusion, while silicon and germanium have been the mainstays of transistor technology, the quest for faster, smaller, and more efficient devices is driving the exploration of new materials. Graphene, molybdenum disulfide, and compound semiconductors like gallium nitride and indium gallium arsenide represent promising alternatives that could potentially overcome the limitations of traditional materials. As research progresses, these new materials may pave the way for the next generation of electronic devices, heralding a new era in transistor design and technology.

KÜSIMUSED JA VASTUSED

1. What are the two materials normally used to construct transistors?

– Silicon and Germanium.

2. Why is silicon commonly used in transistors?

– Silicon has excellent electrical properties and is abundant and cost-effective.

3. What is a key advantage of using germanium in transistors?

– Germanium has higher electron mobility, which can result in faster transistor operation.

4. Are there any other materials used in specialized transistors?

– Yes, materials like Gallium Arsenide (GaAs) are used in high-frequency applications.

5. What is a primary drawback of using germanium compared to silicon?

– Germanium has a lower thermal stability and higher leakage currents.

Kokkuvõte

The two materials normally used to construct transistors are silicon and germanium. Silicon is the most commonly used material due to its abundance, cost-effectiveness, and excellent semiconductor properties. Germanium, while less common, is used in specific applications where its higher electron mobility can be advantageous.