“Potentiometer: Understanding Its Definition, Varied Types, and Working Principle”

Introducción

A potentiometer is an electrical component used to measure and adjust voltage levels in a circuit. It functions as a variable resistor, allowing for precise control over electrical parameters. There are several types of potentiometers, including rotary, linear, and digital potentiometers. The working principle of a potentiometer involves a resistive element and a sliding contact (wiper) that moves along the element, changing the resistance and thereby adjusting the voltage output. This makes potentiometers essential in applications such as volume control in audio equipment, tuning circuits, and as position sensors in various devices.

Understanding Potentiometers: Definition and Basic Concepts

A potentiometer, often referred to as a “pot,” is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider. In essence, it is a variable resistor that allows for the control of electrical devices by adjusting the resistance within a circuit. This fundamental component is widely used in various applications, ranging from simple volume controls in audio equipment to more complex functions in industrial machinery.

To understand potentiometers, it is essential to grasp their basic concepts and how they operate. At its core, a potentiometer consists of a resistive element, a sliding contact (wiper), and three terminals. The resistive element is typically made of carbon or a composite material, and it forms a continuous path between the two outer terminals. The wiper, which is connected to the third terminal, moves along the resistive element, thereby changing the resistance between the wiper and each of the outer terminals. This movement allows for the adjustment of the output voltage, making the potentiometer a versatile tool in controlling electrical circuits.

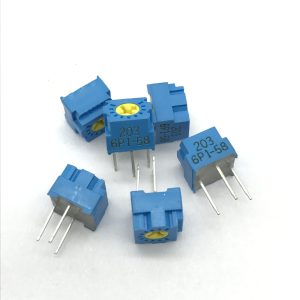

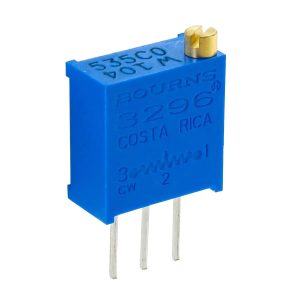

There are several types of potentiometers, each designed for specific applications and environments. The most common types include rotary potentiometers, linear potentiometers, and digital potentiometers. Rotary potentiometers are perhaps the most familiar, featuring a rotating knob that adjusts the resistance. These are commonly found in consumer electronics, such as radios and televisions, where they are used to control volume, brightness, and other settings. Linear potentiometers, on the other hand, have a sliding mechanism that moves in a straight line. These are often used in applications requiring precise control, such as in laboratory equipment or as position sensors in industrial machinery. Digital potentiometers, or digipots, are a more modern variant that uses digital signals to adjust resistance. These are particularly useful in applications where precise and repeatable adjustments are necessary, such as in automated systems and microcontroller-based projects.

The working principle of a potentiometer is relatively straightforward. When a voltage is applied across the two outer terminals, a potential difference is established along the resistive element. As the wiper moves along this element, it taps into different points, effectively dividing the voltage. The voltage at the wiper terminal is a fraction of the total voltage, determined by the position of the wiper. This adjustable voltage can then be used to control other components in the circuit, such as amplifiers, motors, or light dimmers.

In practical applications, potentiometers are valued for their simplicity and reliability. They provide an easy and intuitive way to adjust electrical parameters without the need for complex circuitry. However, it is important to consider factors such as the power rating, resistance range, and mechanical durability when selecting a potentiometer for a specific application. Over time, the resistive element and wiper can wear out, leading to inaccuracies or failure. Therefore, regular maintenance and proper usage are crucial to ensure the longevity and performance of potentiometers.

In conclusion, potentiometers are indispensable components in the realm of electronics, offering a straightforward means of adjusting resistance and controlling various electrical parameters. By understanding their definition, types, and working principles, one can appreciate the versatility and importance of these devices in both everyday gadgets and sophisticated industrial systems. Whether in a simple volume control or a complex automated process, potentiometers continue to play a vital role in the efficient and effective management of electrical circuits.

Exploring Different Types of Potentiometers: Rotary, Linear, and Digital

Potentiometers are versatile components widely used in electronic circuits to control voltage and current. They come in various types, each suited to specific applications. Among the most common types are rotary, linear, and digital potentiometers. Understanding the differences between these types and their working principles can help in selecting the right potentiometer for a given application.

Rotary potentiometers are perhaps the most familiar type. They consist of a resistive element and a rotating wiper that moves along the element to vary the resistance. The user can adjust the resistance by turning a knob, which in turn changes the voltage or current in the circuit. Rotary potentiometers are commonly used in audio equipment, where they serve as volume controls, and in various other applications requiring manual adjustment of electrical parameters. Their ease of use and reliability make them a popular choice for many consumer electronics.

Transitioning to linear potentiometers, these devices operate on a similar principle but differ in their form factor. Instead of a rotating knob, linear potentiometers feature a slider that moves along a straight path. This linear motion allows for precise control over the resistance, making them ideal for applications where fine adjustments are necessary. For instance, linear potentiometers are often used in industrial machinery and robotics, where accurate positioning is crucial. Their straightforward design and high precision make them indispensable in settings that demand meticulous control.

Moving on to digital potentiometers, these modern devices offer a significant advancement over their analog counterparts. Digital potentiometers use electronic signals to adjust resistance, eliminating the need for physical movement. This feature allows for remote control and automation, which is particularly useful in complex electronic systems. Digital potentiometers are commonly found in applications such as programmable power supplies, automated test equipment, and digital audio systems. Their ability to be controlled via microcontrollers or other digital interfaces provides unparalleled flexibility and precision.

Despite their differences, all potentiometers share a common working principle. They function as variable resistors, with the resistance value adjusted by changing the position of the wiper along the resistive element. This adjustment alters the voltage drop across the potentiometer, thereby controlling the output voltage or current. The fundamental concept remains the same, whether the adjustment is made manually, as in rotary and linear potentiometers, or electronically, as in digital potentiometers.

In conclusion, the choice between rotary, linear, and digital potentiometers depends largely on the specific requirements of the application. Rotary potentiometers are ideal for simple, manual adjustments, while linear potentiometers offer precise control in applications requiring fine-tuning. Digital potentiometers, on the other hand, provide advanced features such as remote control and automation, making them suitable for sophisticated electronic systems. By understanding the unique characteristics and working principles of each type, one can make an informed decision and select the most appropriate potentiometer for their needs.

The Working Principle of Potentiometers: How They Function

Potentiometers, often referred to as “pots,” are fundamental components in various electronic circuits, serving as adjustable voltage dividers. Understanding their working principle is crucial for anyone delving into electronics. At its core, a potentiometer consists of a resistive element, a sliding contact known as the wiper, and three terminals. The resistive element can be made from materials such as carbon, cermet, or conductive plastic, each offering different characteristics in terms of resistance and durability.

To comprehend how potentiometers function, it is essential to first grasp the concept of resistance. Resistance is the opposition to the flow of electric current, and it is measured in ohms. In a potentiometer, the resistive element provides a path for the current, and the wiper moves along this path, altering the resistance between the terminals. This adjustment changes the voltage output, making potentiometers invaluable for applications requiring variable control, such as volume knobs in audio equipment or tuning circuits in radios.

When a potentiometer is connected in a circuit, it typically has three terminals: two fixed terminals at either end of the resistive element and one movable terminal connected to the wiper. By rotating the wiper, the user can vary the resistance between the wiper and the fixed terminals. This variation in resistance directly influences the voltage drop across the potentiometer, thereby adjusting the output voltage. For instance, in a simple voltage divider configuration, the input voltage is applied across the two fixed terminals, and the output voltage is taken from the wiper and one of the fixed terminals. As the wiper moves, the proportion of the input voltage that appears at the output changes, allowing for precise control over the voltage level.

Moreover, potentiometers can be classified into different types based on their construction and application. The most common types include rotary potentiometers, linear potentiometers, and digital potentiometers. Rotary potentiometers are the most widely used and feature a rotating knob to adjust the wiper position. Linear potentiometers, on the other hand, have a slider that moves in a straight line, making them suitable for applications where linear motion is preferred. Digital potentiometers, or digipots, are electronically controlled and offer the advantage of precise adjustments through digital signals, making them ideal for modern electronic devices.

In addition to their basic function as voltage dividers, potentiometers can also be used as rheostats, where only two terminals are utilized. In this configuration, the potentiometer acts as a variable resistor, controlling the current flow in a circuit. This versatility makes potentiometers indispensable in various applications, from simple dimmer switches to complex control systems in industrial machinery.

Furthermore, the accuracy and reliability of a potentiometer depend on factors such as the quality of the resistive material, the precision of the wiper mechanism, and the overall construction of the device. High-quality potentiometers ensure smooth and consistent adjustments, which are critical in applications requiring fine-tuned control. Additionally, advancements in materials and manufacturing techniques have led to the development of potentiometers with enhanced durability and performance, catering to the evolving demands of modern electronics.

In conclusion, the working principle of potentiometers revolves around their ability to vary resistance through the movement of a wiper along a resistive element. This fundamental characteristic enables them to function as adjustable voltage dividers or variable resistors, making them essential components in a wide range of electronic applications. By understanding how potentiometers operate and the different types available, one can appreciate their significance in the realm of electronics and their contribution to the precise control of electrical parameters.

Applications of Potentiometers in Various Industries

Potentiometers, often referred to as pots, are versatile components widely used in various industries due to their ability to measure and control electrical resistance. These devices play a crucial role in numerous applications, ranging from simple volume controls in audio equipment to complex position sensors in industrial machinery. Understanding the applications of potentiometers in different sectors can provide valuable insights into their significance and versatility.

In the consumer electronics industry, potentiometers are commonly found in audio equipment such as amplifiers, radios, and musical instruments. They are used to adjust volume, tone, and balance, allowing users to fine-tune their audio experience. The ability to provide precise control over electrical resistance makes potentiometers ideal for these applications, ensuring that users can achieve the desired sound quality with ease. Additionally, potentiometers are also used in lighting controls, where they enable users to adjust the brightness of lights, creating the perfect ambiance for any setting.

Moving on to the automotive industry, potentiometers are integral components in various vehicle systems. They are used in throttle position sensors, which monitor the position of the throttle valve and provide feedback to the engine control unit (ECU). This information is crucial for optimizing fuel injection and ignition timing, ensuring efficient engine performance. Furthermore, potentiometers are employed in steering angle sensors, which detect the position of the steering wheel and assist in the operation of electronic stability control (ESC) systems. By providing accurate feedback on the steering angle, potentiometers help enhance vehicle safety and stability.

In the realm of industrial automation, potentiometers are indispensable for position sensing and control. They are used in robotic arms and CNC machines to measure the position of moving parts and ensure precise control over their movements. This is particularly important in manufacturing processes where accuracy and repeatability are paramount. Potentiometers also find applications in conveyor systems, where they help regulate the speed and position of conveyor belts, ensuring smooth and efficient material handling. The ability to provide reliable and accurate feedback makes potentiometers essential components in these industrial applications.

The medical industry also benefits from the use of potentiometers in various diagnostic and therapeutic devices. For instance, potentiometers are used in medical imaging equipment such as X-ray machines and MRI scanners to control the position and movement of imaging components. This ensures that medical professionals can obtain clear and accurate images for diagnosis. Additionally, potentiometers are employed in infusion pumps, where they regulate the flow rate of medication, ensuring precise and controlled delivery to patients. The reliability and precision of potentiometers make them invaluable in medical applications where accuracy is critical.

Furthermore, potentiometers are utilized in the aerospace industry for position sensing and control in aircraft systems. They are used in flight control systems to measure the position of control surfaces such as ailerons, elevators, and rudders. This information is vital for the accurate and stable operation of the aircraft. Potentiometers are also employed in cockpit controls, where they enable pilots to adjust various settings such as throttle, flaps, and trim. The robustness and reliability of potentiometers make them suitable for the demanding conditions of aerospace applications.

In conclusion, potentiometers are versatile components with a wide range of applications across various industries. Their ability to measure and control electrical resistance makes them indispensable in consumer electronics, automotive systems, industrial automation, medical devices, and aerospace applications. By providing precise and reliable feedback, potentiometers play a crucial role in ensuring the optimal performance and safety of numerous systems and devices. As technology continues to advance, the importance of potentiometers in various industries is likely to grow, further highlighting their significance and versatility.

Troubleshooting Common Issues with Potentiometers

Potentiometers, often referred to as pots, are essential components in various electronic devices, serving as adjustable voltage dividers. Despite their widespread use and relatively simple design, potentiometers can sometimes present issues that require troubleshooting. Understanding common problems and their solutions can help maintain the functionality and longevity of these components.

One frequent issue with potentiometers is the presence of noise or static, which can manifest as crackling sounds when the knob is turned. This problem is often due to dirt, dust, or oxidation on the resistive track inside the potentiometer. To address this, one can use a contact cleaner spray specifically designed for electronic components. By carefully applying the cleaner and rotating the knob several times, the debris can be dislodged, restoring smooth operation. However, if the noise persists, it may indicate wear on the resistive track, necessitating the replacement of the potentiometer.

Another common problem is the potentiometer becoming unresponsive or having dead spots where the output does not change despite turning the knob. This issue can arise from a broken or worn-out resistive element. In such cases, the only viable solution is to replace the potentiometer, as repairing the internal resistive track is impractical. Ensuring that the replacement potentiometer matches the original specifications, such as resistance value and taper type, is crucial for maintaining the device’s performance.

Intermittent or erratic behavior in potentiometers can also be attributed to poor solder joints or loose connections. Inspecting the solder joints on the potentiometer’s terminals and reflowing any that appear cracked or dull can often resolve this issue. Additionally, checking for loose connections in the wiring and securing them can help stabilize the potentiometer’s performance. If the problem persists, it may be necessary to examine the potentiometer for internal damage or consider replacing it.

In some cases, potentiometers may exhibit a limited range of adjustment, where the full rotation of the knob does not correspond to the expected range of output. This issue can be caused by incorrect wiring or a mismatch between the potentiometer’s specifications and the circuit requirements. Verifying the wiring against the circuit diagram and ensuring that the potentiometer’s resistance value and taper type are appropriate for the application can help resolve this problem. If the potentiometer is correctly wired and specified, but the issue remains, it may be indicative of a faulty component that needs replacement.

Furthermore, mechanical issues such as a stiff or loose knob can affect the usability of a potentiometer. A stiff knob may result from dirt or corrosion in the shaft mechanism, which can be alleviated by applying a small amount of lubricant designed for electronic components. Conversely, a loose knob may be due to wear in the shaft or the knob itself. Tightening any set screws or replacing the knob can often remedy this issue. If the shaft is worn, replacing the potentiometer is the best course of action.

In conclusion, while potentiometers are generally reliable components, they can encounter various issues that impact their performance. By understanding common problems such as noise, unresponsiveness, intermittent behavior, limited adjustment range, and mechanical difficulties, one can effectively troubleshoot and resolve these issues. Regular maintenance, such as cleaning and inspecting connections, can also help prevent many of these problems, ensuring that potentiometers continue to function optimally in their respective applications.

Conclusión

A potentiometer is an electrical component used to measure and adjust voltage levels in a circuit. It consists of a resistive element with a sliding or rotating contact (wiper) that forms an adjustable voltage divider. There are three main types of potentiometers: rotary, linear, and digital. Rotary potentiometers have a circular motion, linear potentiometers have a straight-line motion, and digital potentiometers use digital signals to adjust resistance. The working principle involves varying the position of the wiper along the resistive element, which changes the output voltage proportionally. This allows for precise control of electrical devices and is widely used in applications such as volume controls, tuning circuits, and as adjustable voltage dividers in electronic circuits.