“Precision in Motion, Power in Control – Stepper Motors”

Въведение

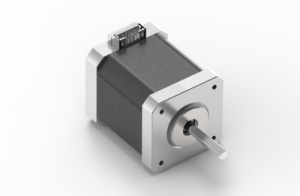

Stepper motors are electromechanical devices that convert electrical pulses into discrete mechanical movements. Unlike traditional DC motors, which rotate continuously when power is applied, stepper motors move in precise, fixed increments or “steps.” This characteristic makes them ideal for applications requiring accurate positioning and repeatable motion, such as in CNC machines, 3D printers, and robotics. Stepper motors operate by energizing coils in a specific sequence, creating a magnetic field that interacts with a rotor to produce movement. Their ability to provide precise control without the need for feedback systems simplifies design and reduces costs, making them a popular choice in various industrial and consumer applications.

Understanding The Basics Of Stepper Motors

Stepper motors are a type of electromechanical device that converts electrical pulses into discrete mechanical movements. Unlike traditional motors, which rotate continuously, stepper motors move in precise, fixed increments, or steps. This unique characteristic makes them particularly valuable in applications requiring precise control of position and speed, such as in robotics, CNC machinery, and 3D printers.

To understand the basics of stepper motors, it is essential to delve into their construction and operating principles. A typical stepper motor consists of a rotor, which is the moving part, and a stator, which is the stationary part. The rotor is usually a permanent magnet or a soft iron core, while the stator is equipped with multiple coils or windings. When electrical pulses are applied to these windings in a specific sequence, they create a magnetic field that interacts with the rotor, causing it to move in discrete steps.

The number of steps per revolution is a critical parameter of stepper motors, determining their resolution. For instance, a motor with 200 steps per revolution has a step angle of 1.8 degrees. This high level of precision is achieved through the careful design of the motor’s internal structure, including the number of poles on the stator and the rotor. Consequently, stepper motors can achieve precise positioning without the need for feedback systems, such as encoders, which are often required in other types of motors.

There are several types of stepper motors, each with its own set of characteristics and applications. The most common types are permanent magnet (PM), variable reluctance (VR), and hybrid stepper motors. Permanent magnet stepper motors use a permanent magnet rotor and are known for their simplicity and cost-effectiveness. Variable reluctance stepper motors, on the other hand, have a rotor made of soft iron and rely on the principle of magnetic reluctance to generate motion. Hybrid stepper motors combine the features of both PM and VR motors, offering higher performance and greater precision.

The operation of stepper motors is governed by the drive circuitry, which controls the sequence and timing of the electrical pulses applied to the windings. This drive circuitry can be as simple as a basic pulse generator or as complex as a microcontroller-based system with advanced algorithms for controlling speed, torque, and position. The choice of drive circuitry depends on the specific requirements of the application, including the desired level of precision, speed, and torque.

One of the key advantages of stepper motors is their ability to maintain a holding torque when stationary. This means that the motor can hold its position firmly without the need for continuous power, making it ideal for applications where maintaining a fixed position is crucial. Additionally, stepper motors exhibit excellent low-speed performance and can achieve very slow and smooth movements, which are essential in applications such as camera platforms and medical devices.

However, stepper motors also have some limitations. They can experience resonance issues at certain speeds, leading to vibrations and loss of synchronization. To mitigate these issues, various techniques such as microstepping and damping can be employed. Microstepping involves dividing each full step into smaller steps, resulting in smoother motion and reduced resonance. Damping techniques, on the other hand, aim to absorb or counteract the vibrations, ensuring stable operation.

In conclusion, stepper motors are versatile and precise devices that play a crucial role in a wide range of applications. By understanding their construction, operating principles, and types, one can appreciate the unique advantages they offer, as well as the challenges they present. With advancements in drive circuitry and control algorithms, stepper motors continue to evolve, offering even greater performance and reliability in the ever-expanding field of automation and control systems.

Applications Of Stepper Motors In Modern Technology

Stepper motors, known for their precision and reliability, have become integral components in various modern technological applications. These motors, which convert electrical pulses into discrete mechanical movements, are particularly valued for their ability to provide precise control over position, speed, and acceleration. This unique capability makes them indispensable in a wide array of industries and applications.

One of the most prominent applications of stepper motors is in the field of robotics. In robotic systems, precise control over movement is crucial for tasks ranging from simple pick-and-place operations to complex assembly processes. Stepper motors enable robots to execute these tasks with high accuracy, ensuring that each movement is repeatable and consistent. This precision is particularly important in industrial automation, where even minor deviations can lead to significant inefficiencies or defects in the final product.

In addition to robotics, stepper motors are extensively used in the medical field. Medical devices such as infusion pumps, blood analyzers, and imaging equipment rely on the precise control offered by stepper motors. For instance, in infusion pumps, stepper motors ensure the accurate delivery of medication at controlled rates, which is vital for patient safety and treatment efficacy. Similarly, in imaging equipment like MRI and CT scanners, stepper motors facilitate the precise positioning of imaging components, thereby enhancing the quality and resolution of the images produced.

The 3D printing industry also heavily relies on stepper motors. In 3D printers, these motors control the movement of the print head and the build platform, allowing for the creation of intricate and detailed objects layer by layer. The precision and repeatability of stepper motors are essential for maintaining the accuracy of the printed objects, especially when dealing with complex geometries and fine details. This has made stepper motors a cornerstone in the advancement of additive manufacturing technologies.

Moreover, stepper motors find applications in the automotive industry, particularly in the control of various subsystems within vehicles. For example, they are used in the actuation of throttle bodies, which control the amount of air entering the engine, thereby influencing the engine’s performance and efficiency. Additionally, stepper motors are employed in the adjustment of headlight angles, ensuring optimal illumination and safety during night driving. The reliability and precision of stepper motors make them suitable for these critical automotive functions.

In the realm of consumer electronics, stepper motors are commonly found in devices such as cameras and printers. In digital cameras, stepper motors control the movement of the lens elements, enabling precise focusing and zooming capabilities. This enhances the overall image quality and user experience. Similarly, in printers, stepper motors drive the print head and paper feed mechanisms, ensuring accurate and consistent printing results.

Furthermore, stepper motors are utilized in aerospace applications, where precision and reliability are paramount. They are used in satellite positioning systems, where accurate control over the orientation and alignment of satellite components is essential for maintaining communication and data transmission. The robustness and dependability of stepper motors make them well-suited for the demanding conditions of space environments.

In conclusion, the versatility and precision of stepper motors have made them indispensable in a wide range of modern technological applications. From robotics and medical devices to 3D printing, automotive systems, consumer electronics, and aerospace, stepper motors play a crucial role in enabling precise and reliable control over mechanical movements. As technology continues to advance, the demand for stepper motors is likely to grow, further cementing their importance in the modern technological landscape.

Comparing Stepper Motors To Servo Motors: Pros And Cons

Stepper motors and servo motors are two prevalent types of motors used in various applications, each with its own set of advantages and disadvantages. Understanding the differences between these two motor types is crucial for selecting the appropriate motor for a specific application.

Stepper motors are known for their ability to divide a full rotation into a large number of steps, providing precise control over angular position. This characteristic makes them ideal for applications requiring accurate positioning, such as 3D printers, CNC machines, and robotics. One of the primary advantages of stepper motors is their simplicity. They do not require feedback systems to maintain position, as they inherently move in discrete steps. This open-loop control system reduces complexity and cost, making stepper motors an attractive option for many applications.

However, stepper motors are not without their drawbacks. One significant limitation is their tendency to lose synchronization if overloaded or if the load changes suddenly. This phenomenon, known as “missing steps,” can lead to inaccuracies in positioning. Additionally, stepper motors can generate significant heat during operation, especially at higher speeds, which can affect performance and longevity. Their efficiency also tends to be lower compared to servo motors, as they draw maximum current regardless of the load.

In contrast, servo motors offer a closed-loop control system, which includes feedback mechanisms such as encoders or resolvers to continuously monitor and adjust the motor’s position. This feedback allows servo motors to maintain precise control over position, speed, and torque, even under varying load conditions. Consequently, servo motors are well-suited for applications requiring high performance and reliability, such as industrial automation, robotics, and aerospace.

One of the key advantages of servo motors is their ability to provide high torque at high speeds, which is often a limitation for stepper motors. This makes servo motors more efficient and capable of handling dynamic loads without losing synchronization. Furthermore, servo motors typically operate more quietly and smoothly compared to stepper motors, which can be beneficial in noise-sensitive environments.

Despite these advantages, servo motors also have their own set of challenges. The complexity of the closed-loop control system can lead to higher costs and increased maintenance requirements. The need for additional components, such as encoders and controllers, adds to the overall expense and complexity of the system. Additionally, the tuning of servo systems can be more intricate, requiring specialized knowledge and tools to optimize performance.

When comparing stepper motors to servo motors, it is essential to consider the specific requirements of the application. For instance, if the primary need is for precise positioning with a relatively simple and cost-effective solution, stepper motors may be the better choice. On the other hand, if the application demands high performance, reliability, and the ability to handle dynamic loads, servo motors are likely to be more suitable.

In conclusion, both stepper motors and servo motors have their unique strengths and weaknesses. The decision to use one over the other should be based on a thorough understanding of the application’s requirements, including factors such as precision, speed, torque, cost, and complexity. By carefully evaluating these factors, one can make an informed choice that ensures optimal performance and efficiency for the intended application.

How To Control A Stepper Motor Using Arduino

Controlling a stepper motor using an Arduino microcontroller is a fascinating and practical application of electronics and programming. Stepper motors are widely used in various applications, from 3D printers to CNC machines, due to their precise control over movement. To understand how to control a stepper motor with an Arduino, it is essential to grasp the fundamental principles of stepper motors and the role of the Arduino in this process.

Stepper motors operate by converting electrical pulses into discrete mechanical movements. Unlike traditional DC motors, which rotate continuously when powered, stepper motors move in fixed increments, or steps. This characteristic allows for precise control over the motor’s position, speed, and direction. Stepper motors typically have multiple coils arranged in phases, and by energizing these coils in a specific sequence, the motor can be made to rotate in small, controlled steps.

To control a stepper motor with an Arduino, one must first connect the motor to the Arduino board. This usually involves using a motor driver or controller, such as the ULN2003 or the A4988, which acts as an intermediary between the Arduino and the stepper motor. The motor driver receives signals from the Arduino and translates them into the appropriate current and voltage levels needed to drive the motor. This setup ensures that the Arduino can control the motor without being damaged by the higher currents required by the motor.

Once the hardware is connected, the next step is to write the Arduino code to control the stepper motor. The Arduino Integrated Development Environment (IDE) provides a convenient platform for writing and uploading code to the Arduino board. The code typically involves including a library, such as the Stepper library or the AccelStepper library, which simplifies the process of controlling the motor. These libraries provide functions to set the speed, direction, and number of steps for the motor.

For instance, using the Stepper library, one can initialize the stepper motor by defining the number of steps per revolution and the pins connected to the motor driver. The setup function in the code sets the initial conditions, while the loop function contains the instructions for the motor’s operation. By calling functions like `step()` or `setSpeed()`, the motor can be made to rotate a specific number of steps at a defined speed. Additionally, the direction of rotation can be controlled by specifying positive or negative values for the steps.

To achieve more advanced control, such as acceleration and deceleration, the AccelStepper library can be used. This library allows for smoother and more precise control over the motor’s movement by managing the acceleration and deceleration profiles. This is particularly useful in applications where sudden changes in speed could lead to mechanical stress or inaccuracies.

In conclusion, controlling a stepper motor using an Arduino involves understanding the motor’s operation, setting up the appropriate hardware connections, and writing the necessary code. By leveraging libraries like Stepper and AccelStepper, one can achieve precise and efficient control over the motor’s movement. This process not only enhances one’s understanding of electronics and programming but also opens up a wide range of possibilities for creating sophisticated and accurate motion control systems.

Troubleshooting Common Issues With Stepper Motors

Stepper motors are widely used in various applications due to their precision and reliability. However, like any mechanical or electronic component, they can encounter issues that may hinder their performance. Troubleshooting these common issues requires a systematic approach to identify and resolve the underlying problems effectively.

One of the most frequent issues with stepper motors is missed steps, which can lead to inaccurate positioning. This problem often arises from insufficient torque, which may be due to an overloaded motor or inadequate current supply. To address this, it is essential to ensure that the motor is not being asked to drive a load beyond its rated capacity. Additionally, verifying that the power supply and driver are providing the correct current can help mitigate this issue. If the current settings are too low, the motor may not generate enough torque to maintain its position, leading to missed steps.

Another common problem is overheating, which can significantly reduce the lifespan of a stepper motor. Overheating typically results from excessive current or prolonged operation at high speeds. To prevent this, it is crucial to monitor the motor’s temperature and ensure it operates within the manufacturer’s specified range. Implementing proper cooling mechanisms, such as heat sinks or fans, can also help dissipate heat more effectively. Moreover, adjusting the current settings to match the motor’s requirements can prevent excessive heat generation.

Stepper motors may also exhibit excessive vibration or noise during operation. This issue is often caused by resonance, which occurs when the motor’s natural frequency matches the frequency of the driving pulses. To minimize resonance, one can adjust the microstepping settings on the driver, which smooths out the motion and reduces vibrations. Additionally, ensuring that the motor is securely mounted and that the mechanical components are properly aligned can help reduce noise and vibration.

In some cases, stepper motors may fail to start or run erratically. This behavior can be attributed to wiring issues, such as loose connections or incorrect wiring configurations. Inspecting the wiring for any signs of damage or misalignment and ensuring that all connections are secure can resolve this problem. Furthermore, verifying that the driver settings match the motor’s specifications is essential for proper operation. Incorrect settings can lead to erratic behavior or failure to start.

Another potential issue is the loss of synchronization between the motor and the controller, which can result in unpredictable motion. This problem often stems from electrical noise or interference affecting the control signals. To mitigate this, one can use shielded cables and ensure proper grounding of the system. Additionally, placing ferrite beads on the cables can help filter out high-frequency noise, improving signal integrity.

Lastly, stepper motors may experience wear and tear over time, leading to decreased performance. Regular maintenance, such as lubricating bearings and inspecting mechanical components for wear, can prolong the motor’s lifespan. Replacing worn-out parts promptly can prevent further damage and ensure consistent performance.

In conclusion, troubleshooting common issues with stepper motors involves a combination of careful inspection, proper maintenance, and appropriate adjustments to the system. By systematically addressing problems such as missed steps, overheating, excessive vibration, erratic behavior, and synchronization loss, one can ensure that stepper motors operate efficiently and reliably in their intended applications.

ВЪПРОСИ И ОТГОВОРИ

1. **What is a stepper motor?**

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements.

2. **How does a stepper motor work?**

A stepper motor works by energizing coils in a specific sequence, causing the motor’s rotor to move in fixed angular steps.

3. **What are the types of stepper motors?**

The main types of stepper motors are permanent magnet, variable reluctance, and hybrid stepper motors.

4. **What is the main advantage of using a stepper motor?**

The main advantage of using a stepper motor is its ability to precisely control position and speed without the need for feedback systems.

5. **What is microstepping in stepper motors?**

Microstepping is a technique used to increase the resolution of a stepper motor by dividing each full step into smaller steps, resulting in smoother motion and finer positioning.

Заключение

Stepper motors are precise, reliable, and versatile devices used in various applications requiring accurate control of position and speed. They operate by converting digital pulses into mechanical rotation, allowing for fine control over movement. Their ability to maintain position without feedback systems, combined with their simplicity and robustness, makes them ideal for use in robotics, CNC machinery, and other automated systems. However, they can suffer from issues like resonance and require careful selection and tuning to match the specific needs of an application. Overall, stepper motors are a critical component in modern automation and control systems.